Steel structures and pipe spools fabrication

Main works during steel structures and pipe spools fabrication:

- Receipt and acceptance of materials required for work performance;

-

Metal marking, flattering, layout and forming. Plate metal cutting is done at plasma-acr cutting table and shearer.

-

Screw-cutting lathe is used for fabrication of flanges and other slugs and items having rotation axis. Profile and pipes cutting is performed at band-sawing machine;

-

Cutting and preparation of fens, holes drilling. Filoing tables with grinding machines are installed in preparation bay. Grinding machines are used to prepare surfaces and ends of slugs for welding. After preparation these slugs are passed to assembly and welding area by bridge crane;

-

In assembly and welding area assembly of finishyed elements is performed from stell structures' and pipe spools' slugs. Assembly and welding area has welding posts; up to 12 various welding activities may be performed in this area at the same time.

Equipment:

-

Plasma-acr cutting table Evolution Steel Max 6000×2000.

Low-carbon steel cut: almost without dross – 32 mm;

- Production cut (burning) – 38 mm;

- Maximum (from edge) – 64 mm;

Stainless steel cut thickness:

- Production cut (burning) - 32 mm;

- Maximum (from edge) - 50 mm;

Aluminum cut thickness:

- Production cut (burning) - 25 mm;

- Maximum (from edge) - 50 mm.

-

Hydraulic shearer QC12K 20×2500. Sheet maximum thickness aloowable for cutting - 20 mm

-

Hydrualic profile bending machine FACCIN RCMI 190

-

3 rolls plate bending machine with double pinch FACCIN 3HEL-1528.

Bend thickness 1500 mm * 20 mm;

Pre-bend thickness 1500 mm * 17 mm;

Shell diameter 1,425 mm;

Yield point 360Н/mm2

Bend thickness 1500 mm * 17 mm;

Pre-bend thickness 1500 mm * 13 mm;

Shell diameter 400;

Yield point 360Н/mm2 ;

-

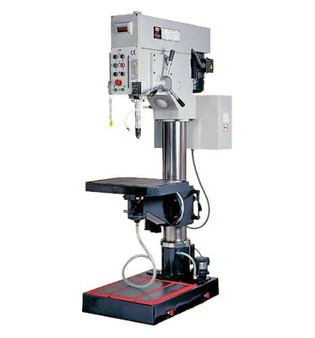

Drilling machine B-1850FE/400. Maximum hole Ø - 50 mm.

-

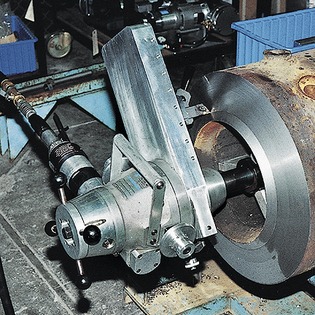

Screw-cutting lathe CU1000. Maximum Ø of a slug - 500 mm>

-

Bandsaw machine Transverse 610.440 DGH — 2 pcs. Maximum cut of a slug when sawing 440×440 mm

-

Hydraulic metal processing machine MULTI 60. Shearing the seet 350×16 mm; punching holes with Ø24 х thickness 15 mm.

-

Universal inverter type welding power supply ESAB Origo Mig 4001i for manual & semi-automatic welding, in set with portable rod feeding mechanism ESAB Origo Feed 3004 with arc power supply.

-

Universal inverter type welding power supply Invertec V-350PRO for manual & semi-automatic welding, in set with portable rod feeding mechanisms LN-25 и LN-15 with arc power supply.

-

Packaged unit for pipe edges processing (pneumatic drive) BEVEL MASTER 224В for processing pipe edge in Ø 8«- Ø 24», a set for flanges processing, set beading tool (enables to extend internal diameter up yo 42").

-

Packaged unit for pipe edges processing (pneumatic drive) 614RBL for cutting pipes with Ø7«- Ø 14» of service pipes and edges processing using external pipe clamps.

Projects:

-

Stroigasconsulting, LLC, Yuzhno-Sakhalinsk

CGTP being a part of Kirinskoye GCF Development Project. Fabrication of steel structures of diverse complexity for construction and assembly activities for Kirinskoye GCF Development Project.

Orenburg PM, LLC, Yuzhno-Sakhalinsk

Fabrication of steel structures for enclosed cold trestle in Okha.

MRTS Engineering, LLC, Yuzhno-Sakhalinsk

Fabrication of large-sized protective steel structures for underwater gas collection facilities as part of investment project for Kirinskoye GCF Development.

Modern Machinery Far East, LLC, Yuzhno-Sakhalinsk

Fabrication of steel structures for warehouse construction located at 1-G Mira Avenue in Yuzhno-Sakhalinsk.

FLUOR, Yuzhno-Sakhalinsk

Cutting, assembly, welding of pipes and pipe spools, thermal treatment, NDE of weld joints, abrasive blasting of pipelines' surfaces, application of anti-corrosive coating and packaging of ready-made items with further transportation.

ECC-VECO, LLC, Yuzhno-Sakhalinsk

Fabrication of steel structures for OPF Chayvo maintenance areas.